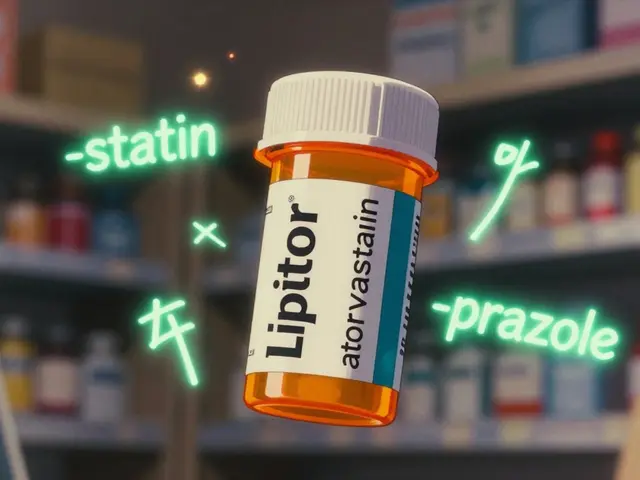

Not all generic drugs are created equal. While most generic pills are simple copies of brand-name drugs-same active ingredient, same dose, same shape-some generics are far more complicated. These are called complex generic drugs. And they’re the reason why, even after decades of generic drug approvals, patients still wait years for affordable versions of certain life-saving medications.

What Makes a Generic Drug "Complex"?

A complex generic drug isn’t just a pill with a different label. It’s a product where the active ingredient, how it’s made, or how it’s delivered to the body is scientifically hard to replicate. Think liposomal injections, long-acting injectables, inhalers with precise dosing mechanisms, or peptides that break down easily in the body. These aren’t your typical tablets you pick up at the pharmacy. The FDA defines complex generic drugs by five key features:- Complex active ingredients-like peptides, polymers, or large molecules that are hard to characterize

- Advanced formulations-such as liposomes (tiny fat bubbles that carry drugs) or nanoparticles

- Specialized delivery systems-like inhalers, patches, or implantable devices

- Drug-device combinations-where the drug and the delivery tool are inseparable

- Unique release profiles-drugs that release slowly over days or weeks, not hours

The Approval Process Isn’t Built for This

The standard path for generics is the Abbreviated New Drug Application (ANDA). It’s called "abbreviated" because it doesn’t require new clinical trials. Generic makers just prove their product is bioequivalent to the brand drug-same absorption, same effect. For a simple pill, that’s easy: measure blood levels over 24 hours, compare, done. But for a long-acting injectable that releases medicine over 30 days? That’s not feasible. You can’t wait a month to check blood levels in 50 people. The FDA can’t use the same rules. That’s why, for complex generics, the ANDA pathway often doesn’t work at all. Instead, companies are forced to use the 505(b)(2) pathway-a hybrid route designed for modified brand drugs. It’s more expensive, requires more data, and takes longer. Many developers don’t even bother. Why spend $40 million and five years when you might still get rejected?Why Bioequivalence Is a Nightmare

Bioequivalence is the golden standard for generic approval. But for complex drugs, measuring "equivalence" is like trying to compare two snowflakes with a ruler. Take inhalers. The drug might be identical. But if the inhaler’s nozzle is 0.1 millimeters wider, the particle size changes. That changes where the drug lands in the lungs. Even if the patient feels no difference, the FDA can’t approve it. The device isn’t just a container-it’s part of the drug. Same with liposomes. The drug inside might be exact, but if the fat coating is slightly thicker, the drug releases too slowly. Too thin? It breaks down too fast. The FDA needs to prove the complex structure behaves the same way in the body. That requires advanced imaging, specialized lab equipment, and tests that didn’t exist 10 years ago. A 2021 review of 24 studies found that analytical challenges were cited in 19 out of 24 papers-the most common hurdle. Developers need tools like cryo-electron microscopy, high-performance liquid chromatography, and dynamic light scattering just to characterize their product. Many small generic companies don’t have access to these.

Regulatory Uncertainty Slows Everything Down

Even when companies try to follow the rules, the rules keep changing. The FDA has tried to help. Under GDUFA II (2017), they created Product-Specific Guidelines (PSGs)-detailed roadmaps for how to approve each complex drug. By 2023, over 1,700 PSGs were published. That sounds good. But here’s the catch: not every complex drug has one. And when a PSG exists, it’s often vague. One company might get told to test particle size. Another gets told to test zeta potential. Both are trying to copy the same brand drug. Experts say the lack of clear, consistent standards creates a guessing game. One company spends $30 million building a test method. The FDA rejects it because they expected a different one. The company has to start over. The Pre-ANDA Meeting Program was created to help companies talk to the FDA early. Over 1,200 meetings have been held since 2017. But even then, outcomes aren’t guaranteed. A meeting doesn’t mean approval. It just means you got feedback-sometimes conflicting feedback-from different FDA reviewers.Costs and Timelines That Scare Off Developers

A simple generic? Development takes 18-24 months. Cost: $2-5 million. A complex generic? 5-7 years. Cost: $20-50 million. That’s not just a bigger budget-it’s a bigger risk. If you invest $40 million and the FDA says "no," you lose everything. Most investors won’t touch it. Big pharma doesn’t want to compete with their own branded drugs. Small generics can’t afford the risk. That’s why, since 2015, only about 15 complex generic drugs have been approved in the U.S.-compared to over 1,000 conventional generics. Meanwhile, the market for complex branded drugs is worth $75 billion a year. Patents are expiring. Patients need cheaper options. But the system isn’t keeping up.

What’s Being Done to Fix It?

The FDA knows this is a problem. In 2023, they pledged to review most new generic applications within 10 months. They hired 128 new reviewers. They’re investing in AI tools to predict how a drug will behave in the body. They’re using machine learning to analyze complex data from particle size to release profiles. Quality-by-design (QbD) is gaining traction. Instead of testing the final product, companies design the manufacturing process to be precise from the start. That reduces variability and gives the FDA more confidence. It’s harder to implement, but it cuts review time by 35-45% for well-prepared applications. The approval of the generic bupivacaine liposome in 2019 was a turning point. It took years of back-and-forth, new testing methods, and close FDA collaboration. But it proved it could be done. Since then, a few more have followed-like generic versions of extended-release injectables for opioid addiction. Still, progress is slow. The FDA admits complex generics will remain a "high-priority, high-challenge" category for years to come.Why This Matters to Patients

You might think, "So what? There are still plenty of generics." But when a complex drug has no generic, patients pay hundreds or thousands of dollars per dose. Think cancer treatments, long-acting pain relievers, or inhalers for severe asthma. These aren’t optional. They’re essential. And when only one company makes the drug, prices stay high. Even if a generic finally gets approved, it might take another year or two before pharmacies can stock it. Patients wait. Doctors wait. Families wait. Some experts argue the FDA should include patient input in approval decisions. If a drug is the only option for a rare condition, shouldn’t that matter more than a tiny technical difference in particle size?The Road Ahead

By 2028, complex generics could make up 25% of the global generic drug market. That’s $60 billion in potential savings. But only if the system can adapt. The answer isn’t just more money or more staff. It’s smarter science, clearer rules, and more collaboration. Companies need predictable pathways. Regulators need better tools. Patients need faster access. Until then, the most complex generics will remain the hardest to approve-not because they’re impossible, but because the system wasn’t built for them.Why can’t complex generic drugs use the same approval process as regular generics?

Regular generics use the ANDA pathway, which relies on simple bioequivalence tests-like measuring blood levels over 24 hours. Complex generics, like liposomal injections or inhalers, release drugs slowly or depend on precise delivery devices. Standard blood tests can’t capture how these work in the body. The FDA needs specialized methods to prove they behave the same way, which the ANDA pathway doesn’t support.

What’s the difference between an ANDA and a 505(b)(2) application?

An ANDA is the standard route for generics-it relies on the brand drug’s safety data and only requires proof of bioequivalence. A 505(b)(2) application is a hybrid path. It can use some of the brand’s data but requires new studies for changes in formulation, delivery, or dosage. For complex generics, this is often the only viable route because they can’t meet ANDA requirements. But it’s more expensive and slower.

Why are there so few approved complex generics compared to regular ones?

Complex generics cost 5-10 times more to develop and take 2-3 times longer. Many companies can’t afford the risk. The FDA also lacks clear, consistent guidelines for many products, leading to unpredictable reviews. Since 2015, only about 15 complex generics have been approved in the U.S., while over 1,000 conventional generics received approval in the same period.

Do other countries have the same problems with complex generics?

Yes. China’s NMPA often requires local clinical trials and a local agent, making approval take up to two years. Brazil’s ANVISA demands strict bioequivalence testing and certified labs. Even the EU has stricter requirements for complex products than the U.S. The U.S. leads in developing guidance, but global inconsistency still slows access.

What’s being done to speed up approval of complex generics?

The FDA has expanded its Pre-ANDA Meeting Program, published over 1,700 Product-Specific Guidelines, and hired 128 new reviewers. They’re using AI and machine learning to analyze complex data, and promoting quality-by-design approaches that reduce variability. The approval of the generic bupivacaine liposome in 2019 proved collaboration works. But progress is still slow because the science is inherently difficult.

Jessica Chambers

15 November, 2025 17:57 PMThis is why my asthma inhaler costs $500 even though the active ingredient is 30 years old. The device is the drug. The FDA treats it like a toaster you can just reverse-engineer. It’s not. It’s a precision instrument wrapped in a placebo.

And yet, somehow, we still expect generics to be cheap. Welcome to healthcare capitalism.

Ryan Airey

17 November, 2025 01:21 AMLet’s be real. This isn’t about science. It’s about pharma playing the long game. They let patents expire but make the generic path so expensive and confusing that no one dares to try. Then they buy up the few companies that do succeed. Classic monopoly behavior. The FDA’s just the frontman.

Jonathan Dobey

17 November, 2025 18:42 PMWe’re not talking about pills anymore. We’re talking about nano-sculpted biological time capsules. The FDA is trying to regulate quantum physics with a ruler. You can’t measure the soul of a liposome with HPLC. You need metaphysics. Or at least a better metaphor.

And yet, we still expect the same regulatory framework that worked for aspirin to handle something that behaves like liquid memory. This isn’t innovation. It’s institutional dementia.

Ogonna Igbo

19 November, 2025 05:01 AMAmerica thinks it’s the only one that can make drugs. Nigeria makes generics too. We don’t have cryo-EM machines but we make medicine that works. Why? Because we don’t care about 0.1mm nozzle differences. We care if the patient breathes. The FDA is lost in its own bureaucracy. Real people need medicine now, not perfect data.

Shyamal Spadoni

20 November, 2025 02:03 AMYou think this is about science? Nah. This is about the FDA being paid off by Big Pharma to delay generics. Why? So they can keep charging $10k for a single shot of some cancer drug. The particle size thing? Total BS. They just need an excuse to say no. And guess who gets to pay? The sick. The poor. The elderly. The system is rigged. Always has been.

Chris Bryan

21 November, 2025 20:26 PMThis is why I don’t trust the FDA. They’re all about control. They don’t want generics because then people stop trusting brand names. And if people stop trusting brand names, what’s left? Nothing. The whole pharmaceutical industry is built on fear. And fear sells. So they make it impossible to copy. That’s not science. That’s propaganda.

John Foster

23 November, 2025 03:25 AMThere’s a deeper philosophical layer here that nobody’s talking about. We’ve reduced medicine to a set of measurable variables - particle size, zeta potential, release kinetics - as if the human body is a machine that can be perfectly replicated. But biology isn’t engineering. It’s chaos. It’s emergence. It’s unpredictability wrapped in flesh. When we demand perfect equivalence in something that’s inherently non-linear, we’re not protecting patients - we’re imposing a false god of precision onto a realm that thrives on ambiguity. The FDA doesn’t want to approve these drugs because they can’t control them. And control, in the end, is the only thing they really value.

BABA SABKA

24 November, 2025 21:54 PMYou’re all overthinking it. The problem is simple: no one wants to pay for the R&D. The FDA doesn’t need more reviewers. They need to stop acting like a lab and start acting like a regulator. If the active ingredient is the same and the delivery system is functionally equivalent - even if you can’t measure every damn nanoparticle - approve it. Let the market sort it out. If it doesn’t work, people won’t buy it. Simple. Not rocket science. Just common sense.

ASHISH TURAN

26 November, 2025 03:00 AMI’ve worked in a generic lab in India. We made a generic inhaler that passed bioequivalence in 12 patients. The FDA rejected it because the aerosol plume was 7% wider. We didn’t have a $2M cryo-EM machine. We had a $50K spray chamber and a lot of patience. The system isn’t broken - it’s designed to exclude anyone who isn’t a billionaire.

Hollis Hollywood

27 November, 2025 04:25 AMI’ve had a family member on a long-acting injectable for chronic pain. The brand version cost $8,000 a month. We waited three years for a generic. When it finally came, it was $1,200. That’s life-changing. But I know so many people who gave up. Who switched to opioids because they couldn’t afford the brand. This isn’t just about science or regulation. It’s about who gets to live. And that’s the real cost.

Aidan McCord-Amasis

28 November, 2025 10:53 AMThis is why I hate healthcare. 🤬

Adam Dille

30 November, 2025 04:50 AMHonestly? I’m just glad any of these are getting approved at all. The fact that we’re even talking about liposomes and nanoparticles in a generic context is wild. I remember when generics were just ‘same pill, cheaper price.’ Now we’re in sci-fi territory. The system’s messy, yeah. But someone’s trying. And that’s more than I can say for most industries.